AI in PCB Manufacturing: What’s Changing and What’s Next

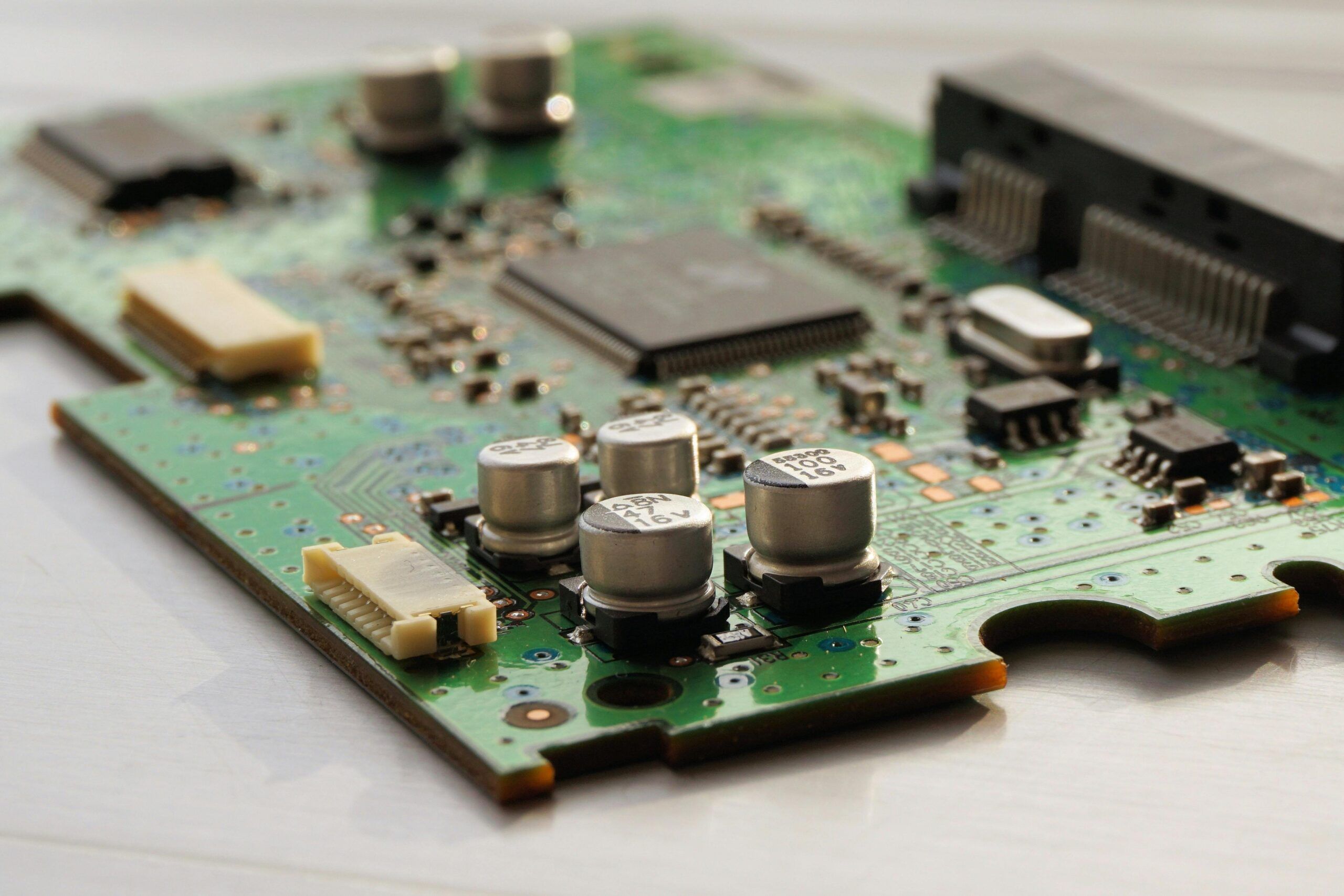

When most people think about artificial intelligence (AI), they picture self-driving cars, smart speakers, or chatbots.But AI and machine learning (ML) are starting to make waves in the world of PCB design, manufacturing, and supply chain management too — and the impact could be huge. Smarter Designs, Faster Builds AI-powered tools are helping engineers design