The Human Factor in Cybersecurity

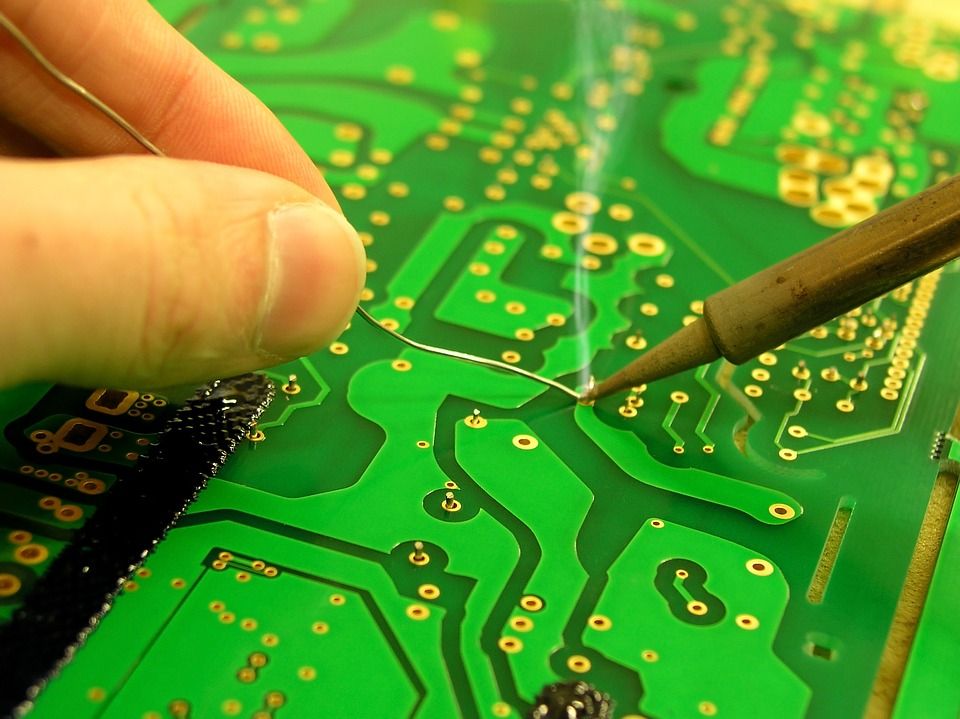

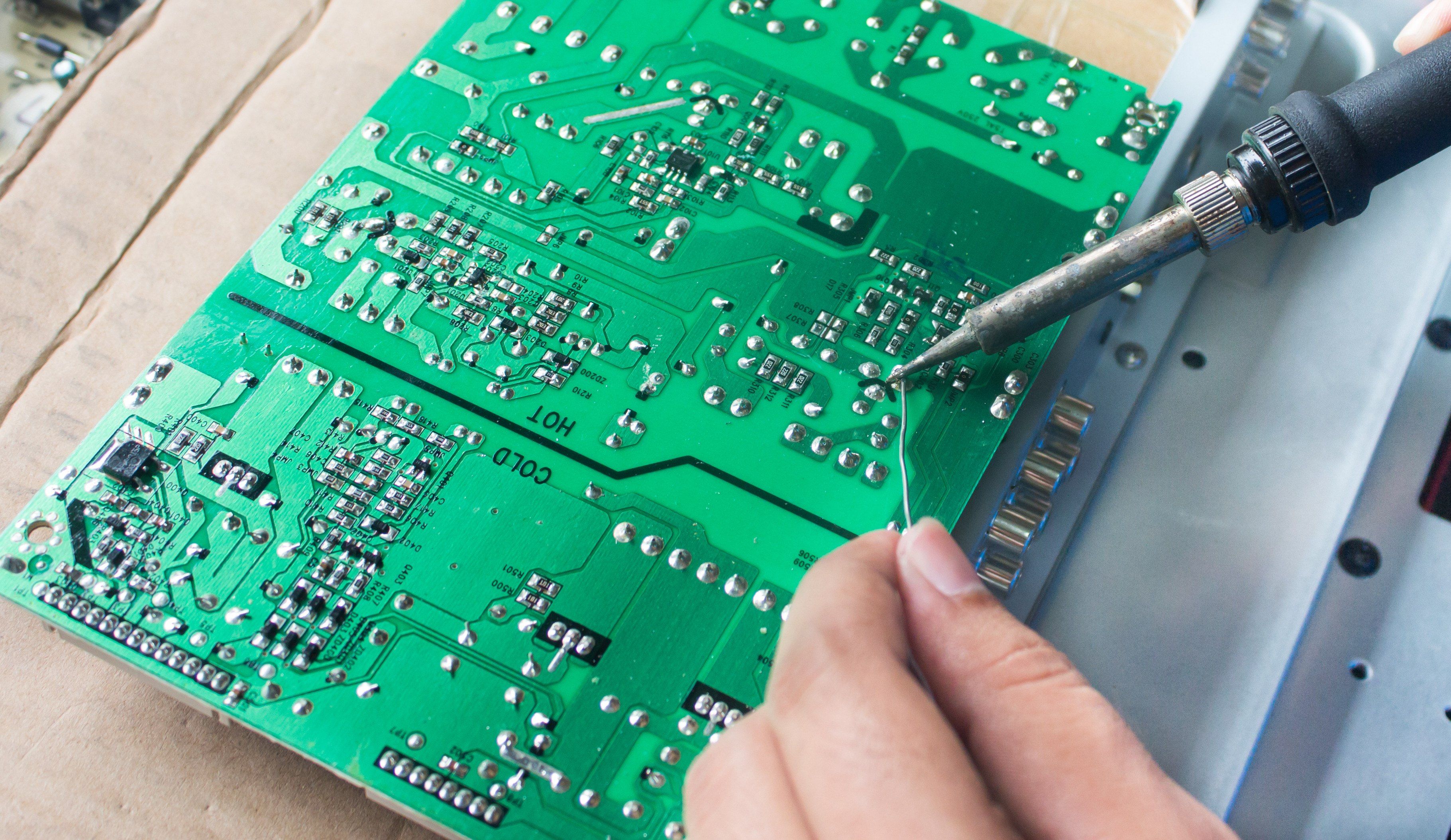

Silicon Safeguards: Securing the Circuit Board Supply Chain Part 3: The Human Factor in Cybersecurity “Amateurs hack systems; professionals hack people.” (Schneier, 2011) In the first two parts of this series, we have looked at some of the base-level concepts to explore to begin to protect your company from cybersecurity threats. Through some planning and