When most people think about artificial intelligence (AI), they picture self-driving cars, smart speakers, or chatbots.

But AI and machine learning (ML) are starting to make waves in the world of PCB design, manufacturing, and supply chain management too — and the impact could be huge.

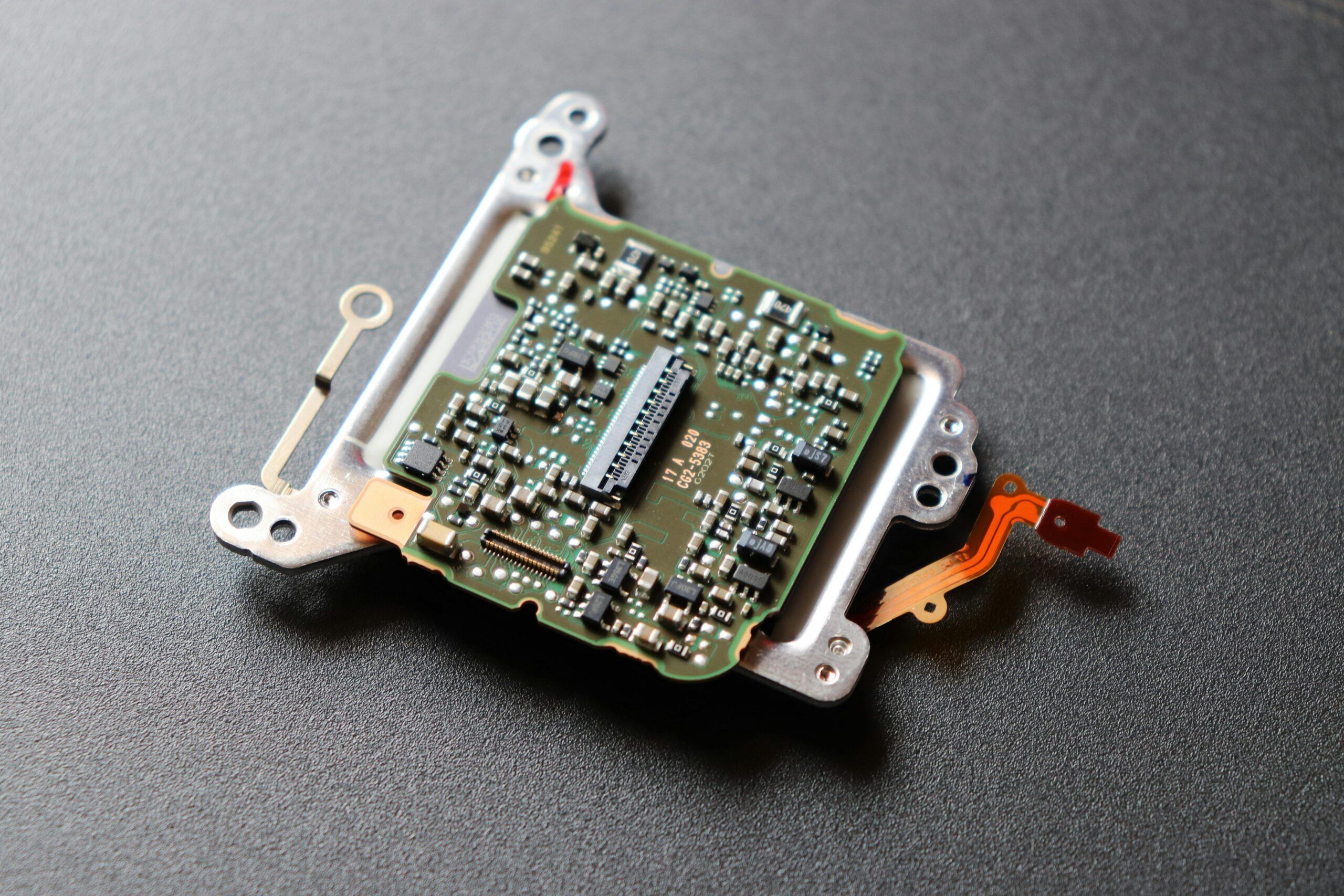

Smarter Designs, Faster Builds

AI-powered tools are helping engineers design better PCBs, faster.

For example:

-

PCB Layout Optimization: AI can suggest more efficient component placement and routing, improving electrical performance and reducing signal loss.

-

Defect Prediction: Machine learning algorithms can predict manufacturing defects based on design files and historical production data — before a single board is built.

-

Yield Improvement: By analyzing large datasets, AI can find patterns that human eyes might miss, leading to higher yields and fewer costly production errors.

This means faster development cycles, better board quality, and lower costs over time.

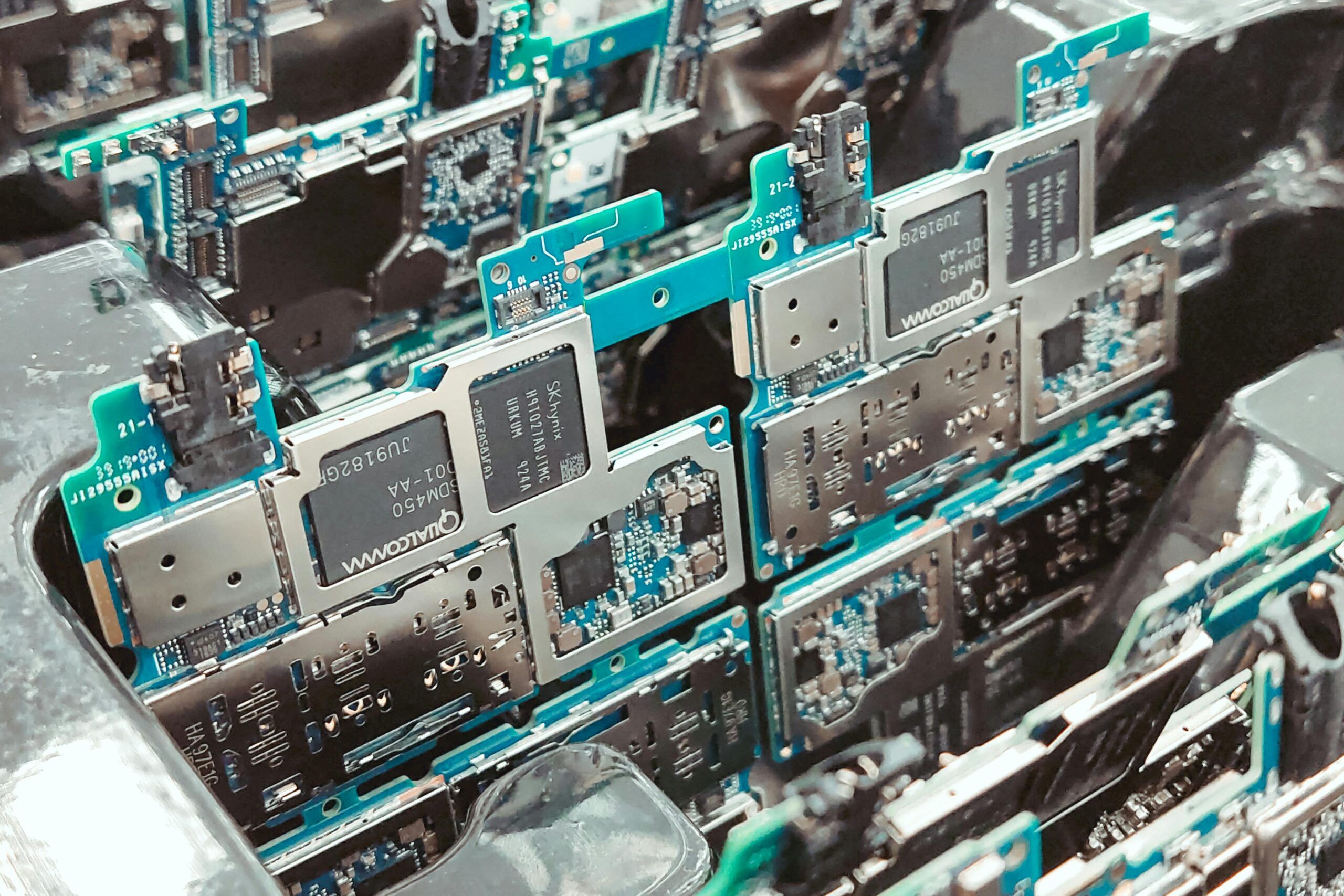

AI in the Supply Chain

Beyond design and manufacturing, AI is starting to reshape supply chains too.

New systems can predict potential supply disruptions based on global events, optimize order timing to avoid shortages, and even recommend alternate parts when lead times spike.

For companies juggling complex BOMs and tight schedules, these AI-driven insights could be a game-changer.

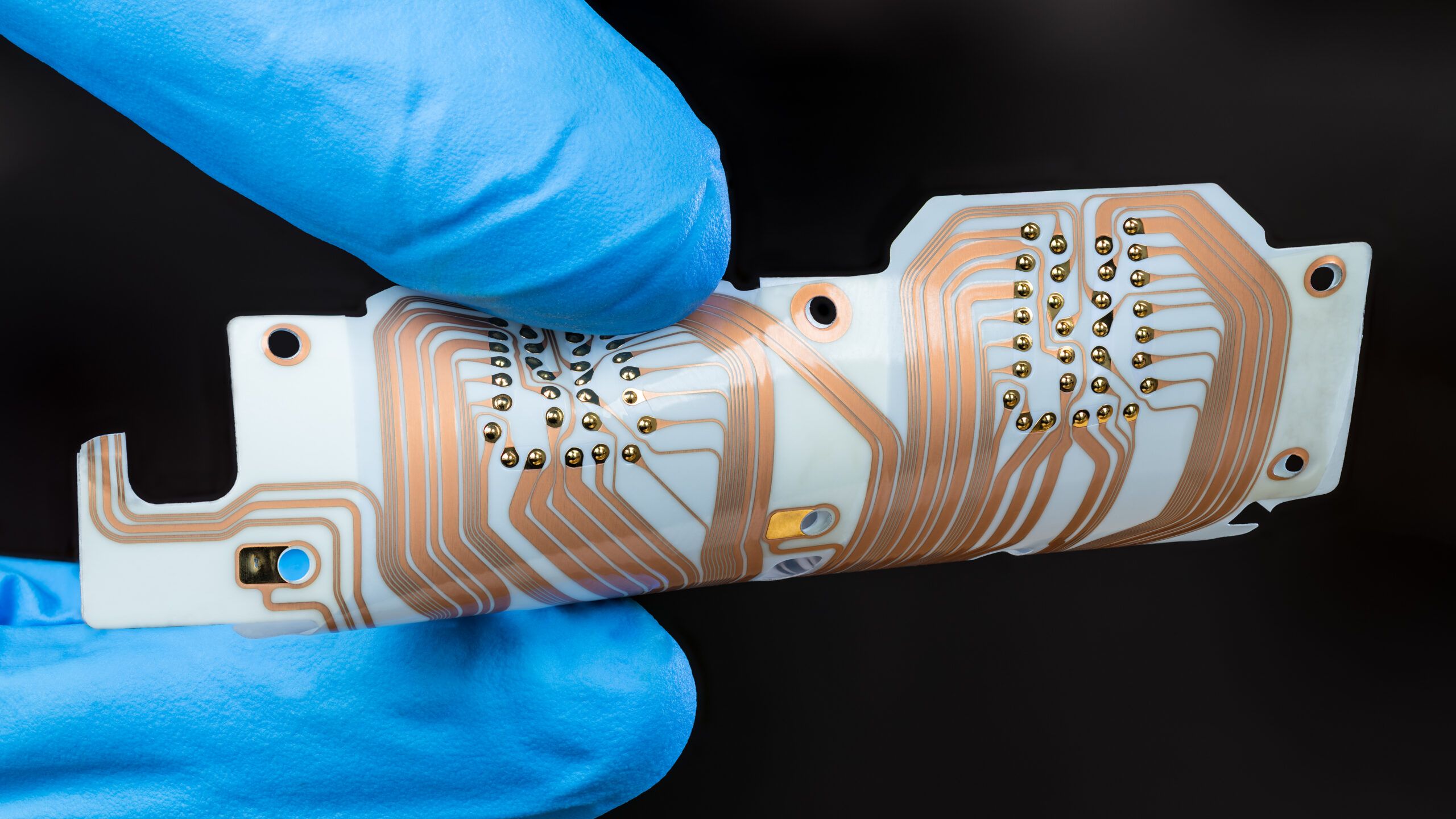

What It Means for You

While AI adoption is still in its early stages across the PCB industry, the direction is clear: smarter, faster, more resilient manufacturing is coming.

At CIC, we keep a close eye on emerging technologies — not to chase trends, but because we believe innovation helps us serve our customers better.

By staying informed, flexible, and connected to trusted partners, we can help you navigate the changes ahead.

Curious how today’s innovations could impact your next project? We’d love to help you stay ahead of the curve.