Businesses are being challenged more than ever! If the product requires a printed circuit board, the hurdles are now multiplied. With numerous staff required to work from home while customer expectations and timelines are still in place, outsourcing becomes the critical key to success.

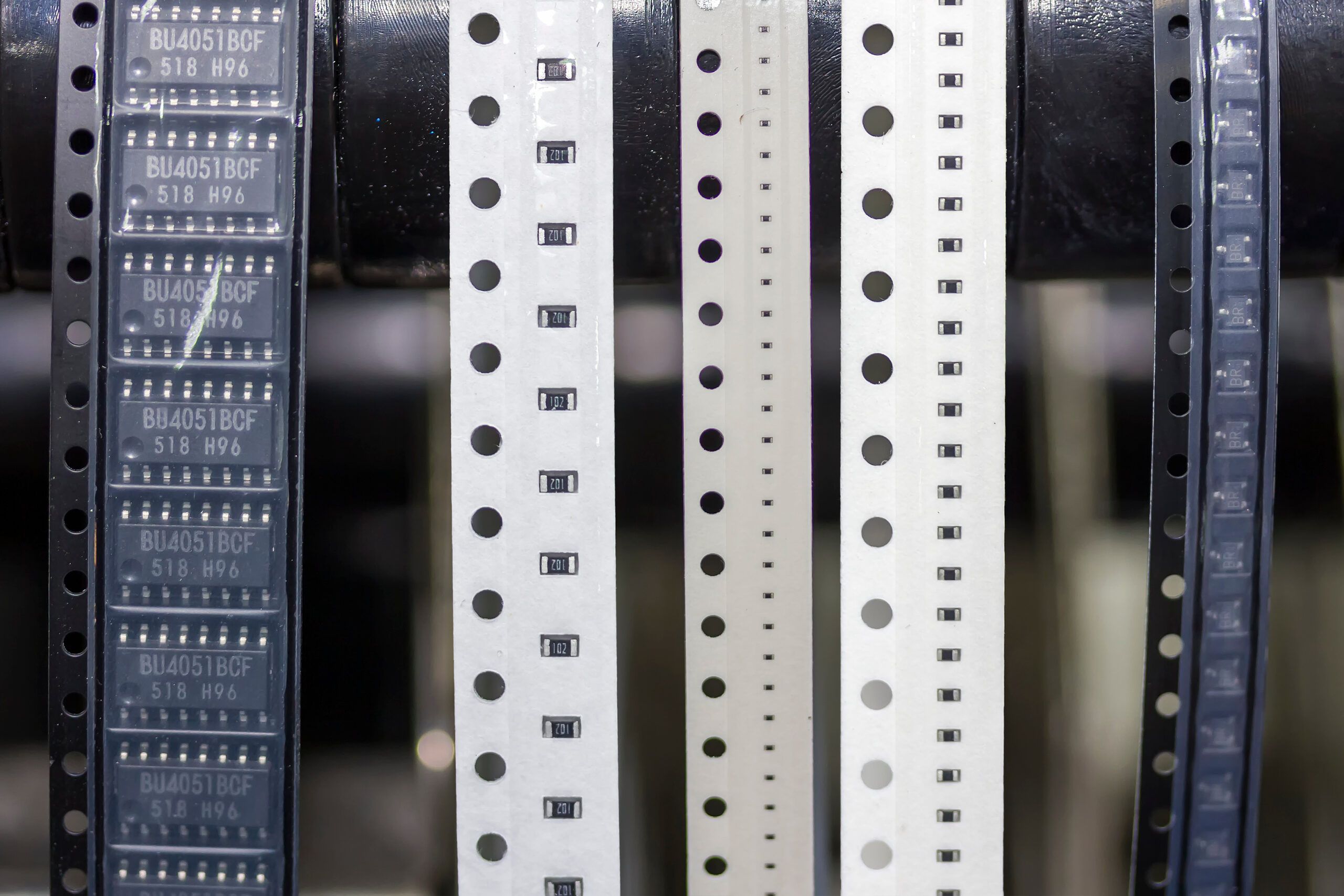

At one time outsourcing was a way to eliminate routine, low skill, business functions. The other side of outsourcing is that it can be a great tool for efficiency and growth of business. Procurement outsourcing and kitting of electronic components has earned its place as a key advantage for high-end, technical business applications (OEM’s and EMS providers alike).

Outsourcing procurement and kitting of electronic components makes use of specialists with skills, assets, and expertise that are specific to your industries needs. This kind of expertise allows a fluid transition from concept to creation, allowing you to focus on the core competencies of your business. Your procurement specialist has the contacts, expertise, and buying leverage to see your project to completion on time and on budget.

Advantages:

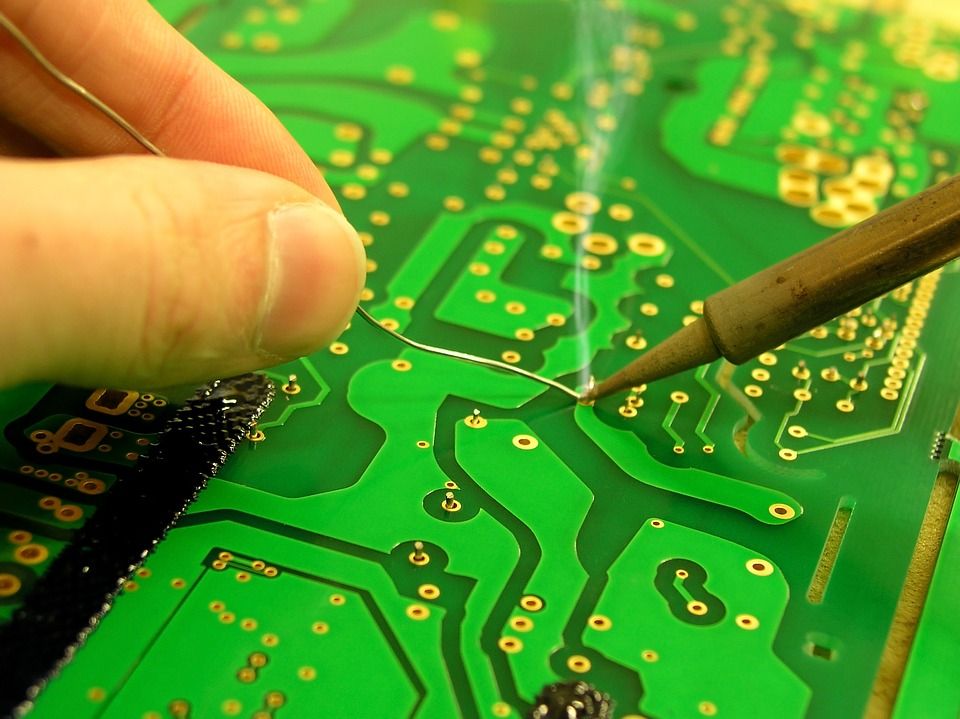

- Reduce purchasing impact of adding multiple new suppliers and purchase order costs

- Eliminate time/cost of receiving, verifying in-bound materials and inventory accounting

- Eliminate the warehouse demand to pick and pack 100’s of lines of materials for PCB assembly

- Reduce design engineering time by receiving suggested available alternates for obsolete items

Outsourcing procurement and kitting through a specialist in the electronics industry means that the risks associated with product procurement, and unexpected costs resulting from erroneous components and the resulting downtime, are minimized.

Consider staff availability, the logistics of handling incoming shipments, the limited PCB assembly access, and outsourcing is the critical key to success.